百達信

- …

百達信

- …

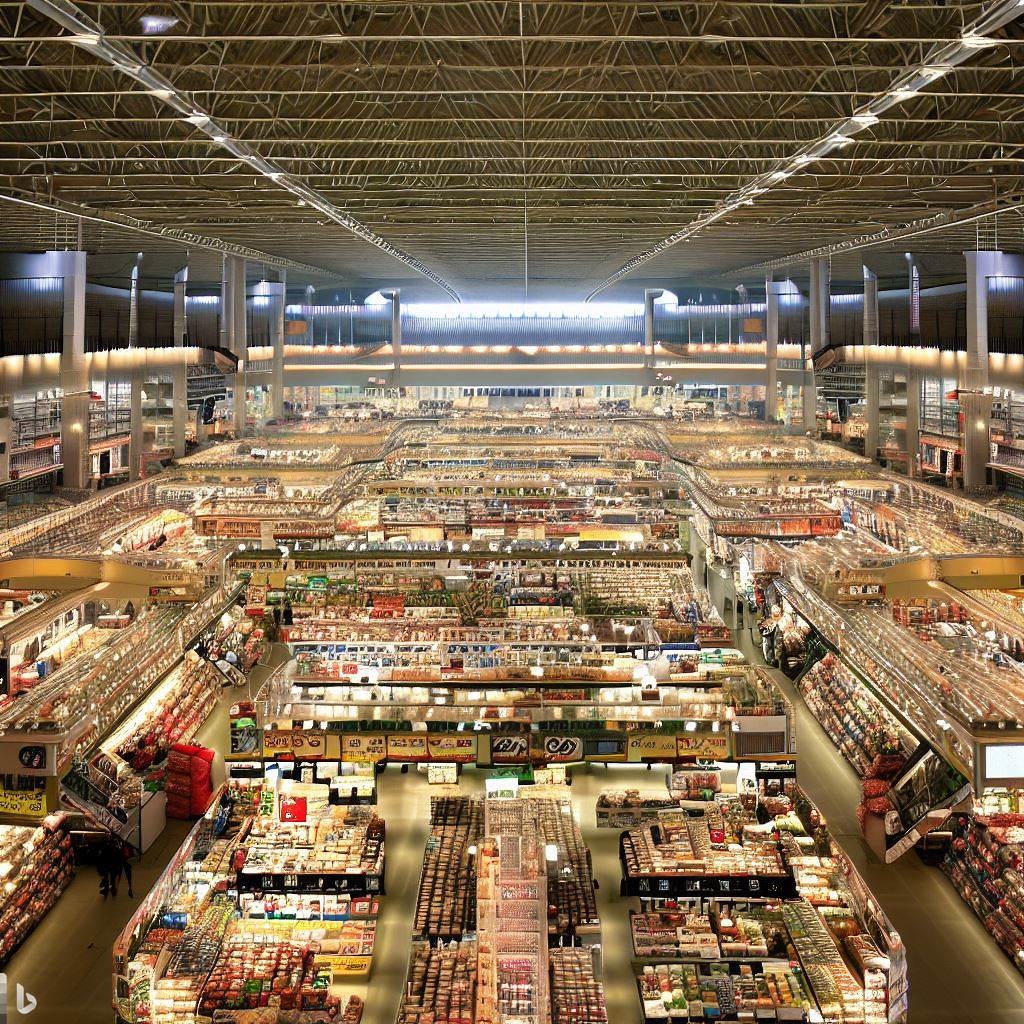

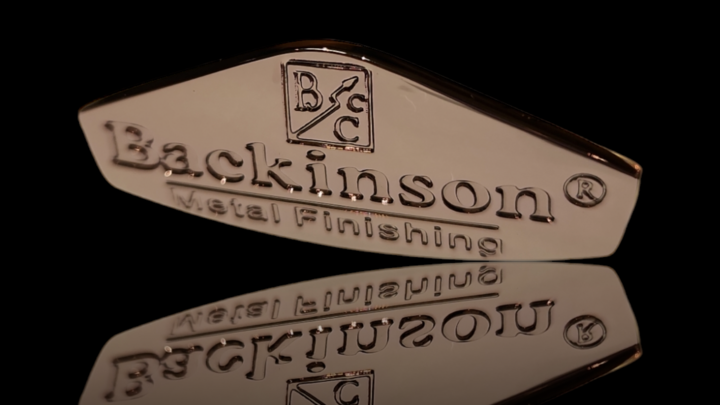

One-stop comprehensive electroplating supplies supermarket

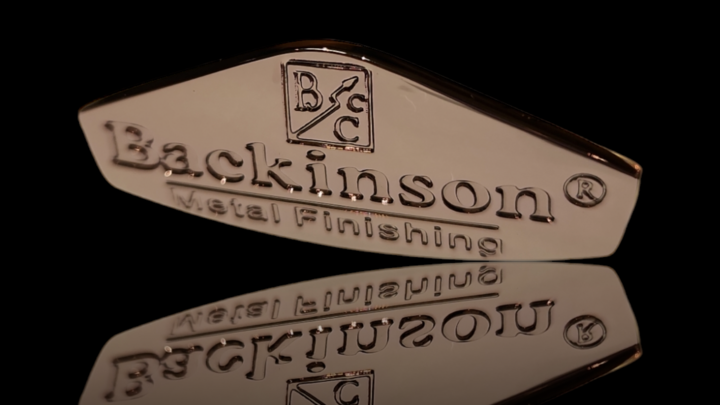

Provide chemical products for metal finishing and electroplating equipment

Ensuring you can enjoy a one-stop procurement experience from the comfort of your office.Please enter your discount promo code.:BACKINSON

All items 5% off!

Cyanide Copper Plating

CA

This product can deposit a bright and fine pure copper coating with fast electroplating speed and easy bath control, making it suitable for both barrel platingand rack plating..

Acid Copper

CS—1080

A highly versatile and easy-to-control bright acid copper electroplating process, delivering rapid leveling with exceptional throwing power. It minimizes thickness variation between high and low current density areas, ensuring superior covering power even in recessed or mesh patterns.

Bright Nickel Plating

110

Achieve high-leveling bright nickel deposits in record time – delivering whiter hues, superior ductility, and effortless operation with exceptional throwing power and adhesion, all while maintaining cost efficiency.

Low-Nickel Content

Bright Nickel RN-3

Bright Nickel RN-3 is a revolutionary low-nickel content electroplating process delivering exceptional brightness and throwing power, operating at 50% nickel content of traditional Watts bright nickel bath – slashing makeup

and operational costs amidst volatile nickel pricing.

Pearl Bright Nickel Plating

PBN-99

Pearl Bright Nickel PBN-99 is designed to deposit mesmerizing satin-white finishes in record time – delivering hypnotic pearl escence with unparalleled visual warmth, crafted for premium decorative applications from jewelry to automotive trim.

Sandy Nickel Plating

SN

Sandy Nickel SN deposits a mechanically-blasted texture onto smooth substrates, blending matte grit with subtle luster for captivating aesthetics. The dense coating resists finger prints, achieves 400-500HV hardness, and delivers exceptional wear resistance that withstands daily abrasion.

Dull Nickel Plating

DL

Dull Nickel DL deposits a purely white, non-leveling nickel layer engineered for critical applications – preserving substrate matte fidelity in heavy deposits, serving as a stress-relieving underlayer for bright nickel, and enhancing pearl nickel's luster beyond lacquer protection.

Heavy Lead-Free White BronzeHCT-56

HCT-56 is an environmentally friendly, lead-free electroplating process for copper-tin-zinc alloy. It deposits a bright, silvery-white coating with a composition of approximately 55% copper, 40% tin, and 5% zinc. Suitable for application after acid copper plating, this process replaces bright nickel as a white coating layer. The deposited white bronze layer can reach a thickness of 5 microns.

Brass Salt

BS-60

BS-60 brass salt is entirely free of cyanides,

facilitating safe transportation and storage.To prepare the brass plating solution:

1. Dissolve a specified quantity of BS-60 brass salt into a sodium cyanide solution.

2. Add the required quantity of ammonium chloride.

The resulting solution forms a ready-to-use brass plating bath with exceptional convenience.

Titanium Color

T-70T-70 is an acid titanium color electroplating process characterized by exceptional bath stability and simplified control parameters. It deposits a uniform,subtle blue-gray finish with a hardness of 750HV, delivering outstanding wear resistance. Suitable for decorative applications, this processis compatible with both rack and barrel plating systems.

Nickel-Free Black Gun Color

GY-90NF

GY-90 NF is engineered specifically for nickel-free black gun color electroplating, offering exceptional bath stability and simplified operational control. It deposits a deep black, uniform finish with superior tarnish resistance and high abrasion durability, making it ideal for decorative applications.

Nickel-Containing Black Gun Color

BK-95BK-95 deposits a jet-black, lustrous coating designed for decorative electroplating applications. Compatible with both rack and barrel plating, this process features exceptional bath stability, user-friendly control, and a wide operating temperature range. The resulting finish exhibits uniform coloration and exceptional covering power.

Heavy Acid Gold Plating

HG 24K

Heavy Acid Gold Plating HG 24K operates effectively across a broad current density range, depositing a highly specular, 24-karat pure gold finish with thicknesses exceeding 10 microns. The coating exhibits uniform coloration, exceptional ductility, and superior corrosion resistance. Beyond decorativemetal plating applications, this process is equally suited for functional electronic plating, delivering excellent electrical conductivity and solderability, with compatibility for both rack and barrel plating systems.

Acid Hard Gold Plating

AHG24K

AHG24K Acid Hard Gold Plating deposits a high-luster, hardened 24K gold coating, capable of producing a thin gold coating. The process offers exceptional bath stability and simplified operational control without disrupting production workflows. Widely adopted in hardware, jewelry, and watchmaking industries, it is compatible with both rack and barrel plating systems.

Acid Gold Plating

HW24KHW24K is a highly cost-effective acid gold plating process that deposits exceptionally pure, vibrant golden coatings with a visually warm, lustrous finish. The bath demonstrates outstanding stability and extended service life, with remarkable tolerance to metallic impurities—common contaminants introduced during operation do not compromise the gold color quality.

Acid Coffee Color Gold Plating

AG-2386

AG-2386 Acid Coffee color Gold Plating Solution deposits a cognac-toned coating with metallic luster, brilliant richness, and enhanced hardness surpassing pure gold, thereby delivering superior wear resistance. Optimized for thin gold plating applications, this process features exceptional bath stability, high impurity tolerance, and extended operational lifespan. It is extensively applied in hardware, jewelry and watch component electroplating.

Neutral Gold Plating

NG 24KNeutral Gold Plating NG 24K deposits a bright, thin gold coating with vivid coloration, ideal for jewelry and decorative applications. The bath offers exceptional stability, user-friendly control, and extended service life, and is compatible with both rack and barrel plating systems.

Rose Gold Plating

RGB

Rose Gold RGB Plating deposits a 4N-5N red-gold coating using a cyanide-based alkaline bath, designed for thin final tinting on gold-plated workpieces.

Eco-Friendly TrivalentChromium Plating

Cr5200

Trivalent Chromium Cr5200 Plating deposits a pure metallic chromium layer, retaining chromium's intrinsic properties including high hardness, exceptional wear resistance, and superior corrosion resistance. The bath utilizes trivalent chromium compounds as the chromium source, free from hexavalent chromium, lead, cadmium and mercury, fully compliant with RoHS standard.

Vertical Hoisting-Type Circular Plating Production Line

- Features a large vertical stroke with linear ascending motion, ideal for longer and wider racking systems.

- The drive mechanism comprises separate horizontal and vertical units, ensuring a compact structure and easy maintenance.

- Supports automated cyclic operation.

- Ensures user-friendly handling.

Barrel Electroplating Production Line

- The production line uses PP material as the main body, equipped with a variable-speed motor. It features light weight and flexible operation, making it suitable for electroplating small parts.

- The small barrel plating machine is suitable for finer workpieces that require barrel plating. It supports forward and reverse rotation as well as automatic time control. Compact in size, it offers flexible operation and low cost.

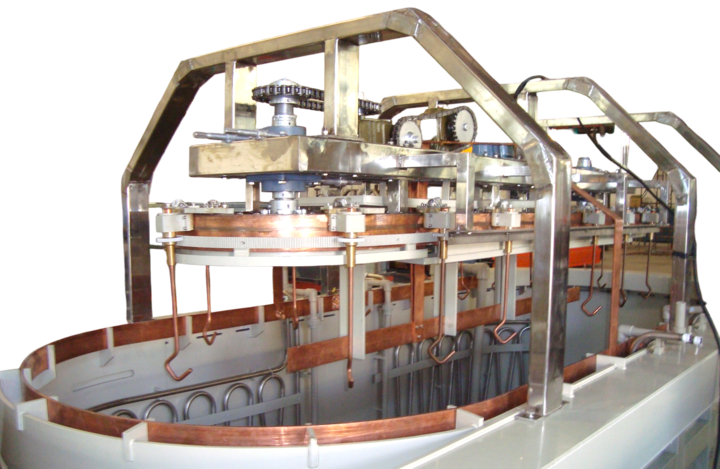

Circular Semi-automatic Rack Plating Production Line

The structure is simple and operation is convenient. It runs automatically in cycles, and the electroplating time can be adjusted freely, making it highly flexible.

Rotary Automatic Stepwise Rinsing Line

- Floor-mounted support: Features good rigidity and high load capacity. A single suspension rod can carry 3 to 4 plating rack fixtures for rinsing.

- Tank-surface support: Designed to be directly installed on existing rinsing tanks, requiring minimal production floor space.

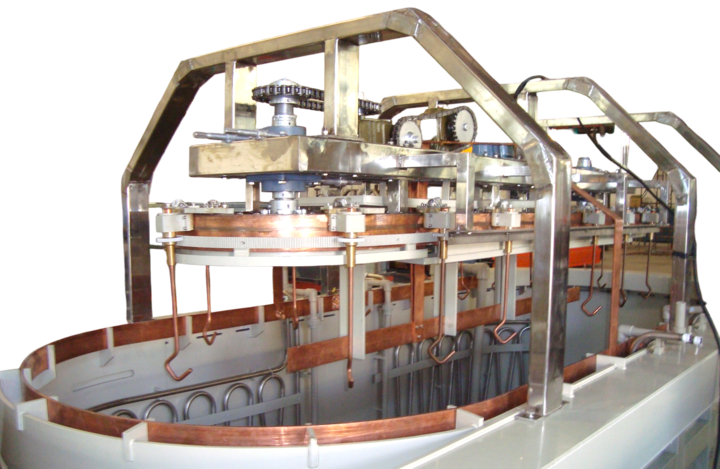

Double-chain Rotary Automatic Stepwise Rinsing Line with Tank-Surface Support and Electrolytic Passivation

In addition to the features of a conventional tank-surface support double-chain rotary automatic stepwise rinsing line, it is designed to meet the requirements of electrolytic degreasing (or electrolytic passivation) in the pre-treatment (or post-treatment) process. Therefore, a copper busbar brush electrical device is installed on the corresponding tank to enable electrolytic operation.

We can customize automatic lines such as gantry lines, vertical lifting lines, and fishing lines according to your requirements. Don’t hesitate—contact us right away!

- Welcome to request FREE plating color samples.

- Don't hesitate! Contact us now to claim your FREE chemical products samples – let our solutions solve your challenges today.

BUY NOW

Explore Our Products

AllElectroplating Auxiliary Equipment 1Electroplating Auxiliary equipment 2Electroplating Equipment Parts & Accessories 1Electroplating Equipment Parts & Accessories 2Electroplating Equipment Parts & Accessories 3Semi-Automatic / Fully Automatic Electroplating Production LineElectroplating Production Line Design & PlanningPre-treatment Degreasing Powder ProductsPre-treatment ProductsCopper Plating AdditivesRack Nickel Plating AdditivesBarrel Nickel Plating AdditivesPearl/Sandy/Dull Nickel Plating AdditivesBrass Plating AdditivesChromium Plating AdditivesBronze Plating AdditivesAcid Tin Plating AdditivesGold Plating AdditivesPalladium Plating AdditivesGun Color Plating ProductsTitanium Color Plating ProductTrivalent Chromium Plating ProductGold Stripper ProductsPost-treatment ProductsElectrophoretic Coating ProcessDeposit StripperLoad More